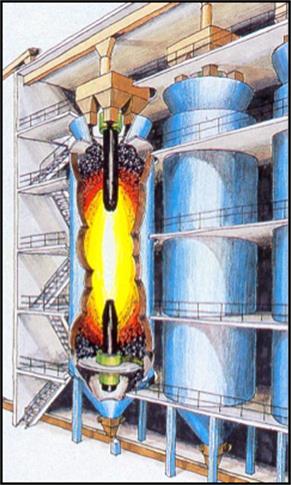

Electrode paste is a conductive material used in ferroalloy furnace, calcium carbide furnace and other electric furnace equipment. The electrode paste is also called self baking electrode, which depends on the heat in the submerged arc furnace to complete the roasting. Therefore, matching the electrode consumption speed with the roasting speed is the key to the use of electrode paste. Due to the development of submerged arc furnace technology, the electrode is gradually developing towards the direction of large-scale and closed. In the roasting process, the more heat conduction and radiant heat obtained by the open furnace in the past can only be reduced for a long time As a result, the heat from the furnace is greatly reduced, which requires improving the sintering performance of electrode paste to make up for this deficiency.

1、 Introduction of electrode paste

Aggregate: 75-80% calcined coal

-Only a few calcined coals are suitable for the production of high quality electrode paste

-Need strict production process control and quality control

Asphalt: 20-25% coal tar

-Coal tar pitch is a common binder in the production of carbon products

-Cohesiveness is a very important index

Softening point of asphalt (global method)

-Cylindrical electrode paste 65-90 ℃

2、 Important index of electrode paste

Unfired electrode paste

Melting of electrode paste (viscosity index)

Volatile matter

Electrode paste after baking

resistivity

mechanical strength

Elastic modulus

Thermal conductivity

Thermal expansion

Crack resistance

Thermal shock resistance

Anti gas reactivity

3、 Quality characteristics

Brand: electrode paste - CYL

Unit

Value

Unfired electrode paste

Ash content

%

5.5

Volatile content

%

13

Fixed carbon

%

82

Bulk density

kg/m3

1600

Softening point

℃

80-90

℃

65-75

Plasticity

%

20-30

%

30-40

%

20-40

Physical properties of paste after roasting

Volume density

kg/m3

1400

Real density

kg/m3

1830

Total porosity

%

24

Electric resistivity

μΩm

70

Compress strength

N/mm2

22

Bending strength

N/mm2

3.5

Young's modulus

k N/mm2

3.0

Thermal conductivity

W/(oK•m)

6

Linear expansion rate

X10-6/℃

4

*All the eigenvalues are based on the average of the experimental control results, and all the results follow the normal distribution, so the above eigenvalues can not be taken as the maximum or minimum. According to the statistical law, 90% of the results are in this range.